A CNC (computer numerical control) punching machine is a tool used in factories to punch holes and shapes into sheets of metal. This machine uses computer programs to control its movements, which makes it very precise and efficient. CNC punching machines are important in many industries, such as automotive, electronics, aeroplanes, and household appliances.

How does a CNC punching machine work?

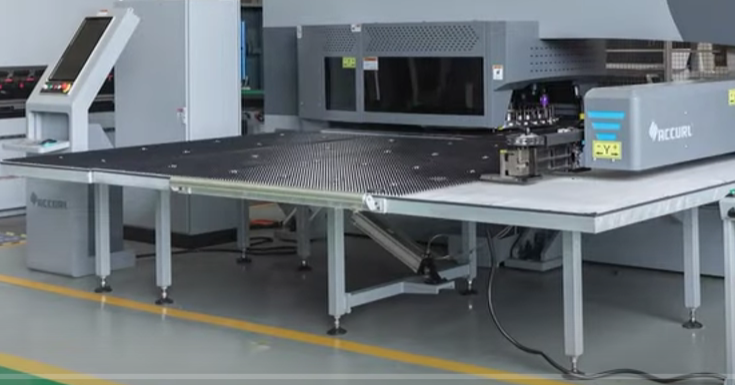

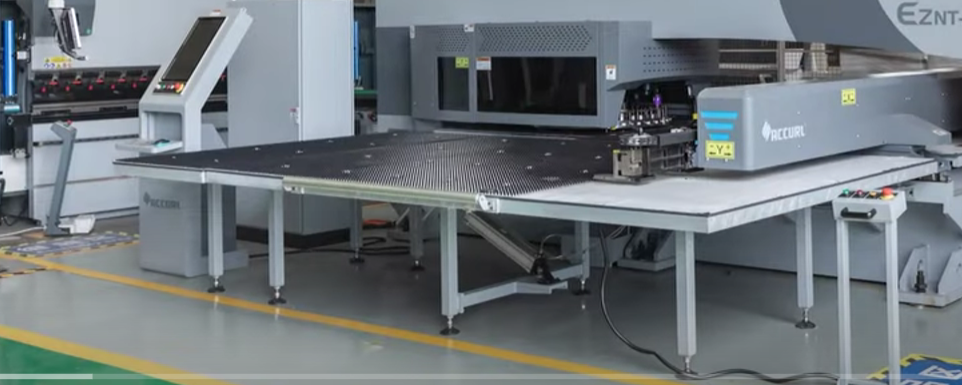

First, engineers create a design on a computer using special software called CAD (computer-aided design). According to Cape Business News, this design is then turned into a CNC program, usually written in a code called G-code. The program tells the machine exactly where to punch the metal and what shapes to make. Once the design is ready, the metal sheet is placed on the machine’s worktable and the CNC controller reads the program to start the punching process.

Punching process

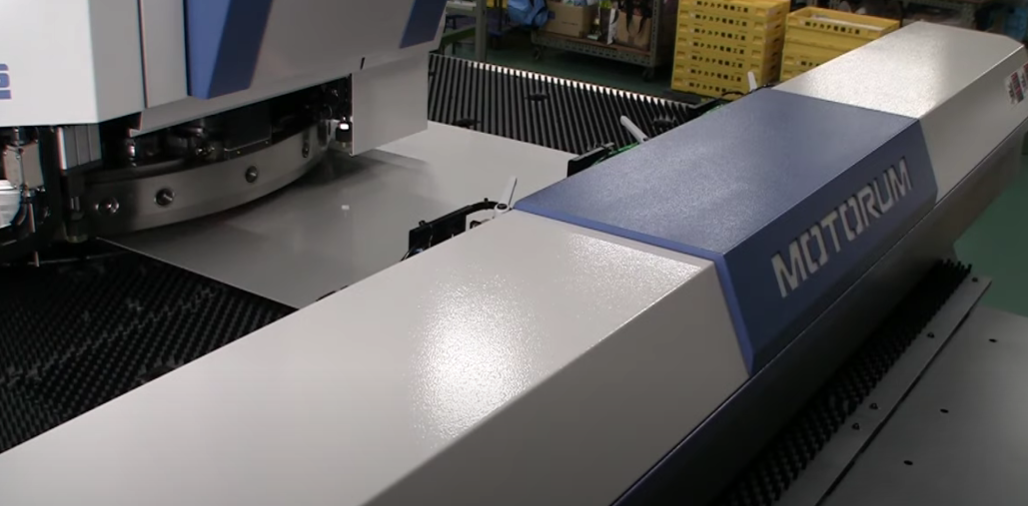

The machine uses a punch and die set to cut or shape the metal. The punch is the tool that presses into the metal, while the die supports the metal from below. When the machine operates, the punch moves down and cuts or shapes the metal sheet. CNC punching machines are very precise, allowing them to create detailed patterns and accurately placed holes.

These machines can perform many different operations, such as making holes, notches, or even 3D shapes in the metal. They have multiple tool stations, so they can switch between different punches and dies automatically during the same job. This feature makes the process faster and reduces the need for manual work.

For those interested in learning more about CNC punching machines, machinery specialists such as cotswold-machinery-sales.co.uk/euromac-bending-machines/punching-machines will be happy to answer your questions.

Benefits of CNC punching machines

CNC punching machines have many advantages over traditional methods. They are very precise, which means they can make parts that fit exactly as needed. The computer control reduces mistakes that people might make, leading to better quality and more consistent results. These machines can also produce large quantities of parts quickly and with less labour, making them more cost-effective for large manufacturing jobs.